With the increasing demand for electronic devices and electric vehicles throughout the world, more and more manufacturers are running into the same problem: the supply of components, especially batteries, is not keeping up with the massive demand. To meet overall demand in time, additional facilities for production of lithium-ion batteries should be built in the short-term. Battery cell production is a mission critical challenge because the materials used in lithium-ion batteries react heavily with humidity. For that reason, we introduced DryCell: a mobile, container-based Plug&Play dryroom solution for R&D environments, in which the proof-of-concept of battery development can be determined before they go into final production.

The production of lithium-ion batteries requires extremely low humidity conditions. Lithium reacts with water vapour and inaccurate humidity control in a battery production area can have severe consequences for operators and their environment, as well as leading to a drop in product quality. The basic principle of dryroom technology is to control the humidity level in a room or chamber by removing moisture from the air. This is typically achieved by using desiccants, which are materials that have a high affinity for water molecules and can effectively absorb moisture from the air. In a typical dryroom, the air is circulated through a series of filters and desiccant beds, which remove any contaminants and moisture from the air. The humidity level is monitored and controlled using sensors and feedback loops, which adjust the operation of the desiccant beds and other equipment as needed to maintain the desired humidity level.

In some cases, dryrooms are also being used by pharmaceutical companies, automotives, special (safety) glass manufacturers, semiconductors, energy storage and selective other industries which have very low dew point requirements for their hygroscopic material processing and storage. Due to the extreme requirement for moisture control, the energy required for this part of the manufacturing process is significant and therefore has a substantial impact on the profitability of any battery manufacturing operation. Many companies are therefore switching to a controlled environment with a dew point of -40°C, which consumes a lot less energy than dryrooms with dew points of -80°C to -100°C.

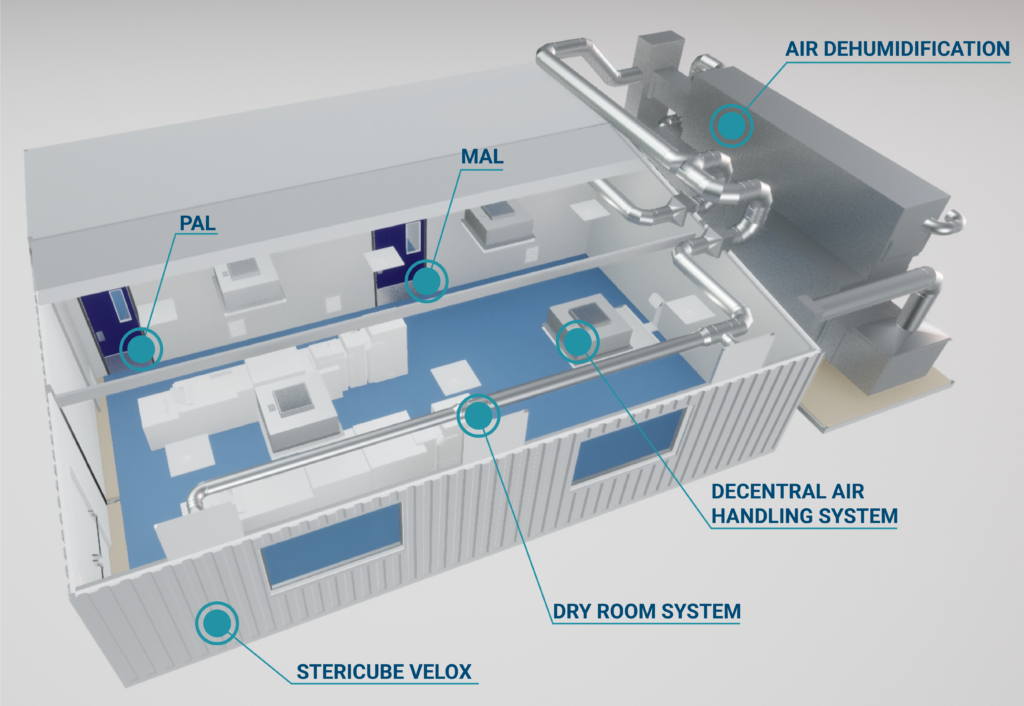

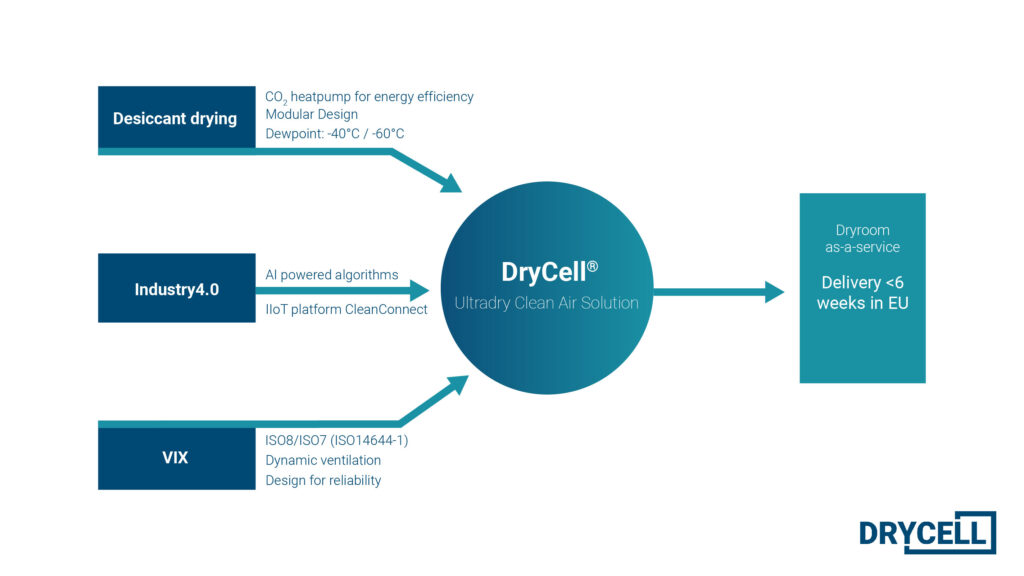

With DryCell, we have developed a unique modular and pre-engineered dryroom/cleanroom combination that allows us to provide manufacturers with a conditioned test facility at very short notice. As standard, this dryroom is supplied in cleanliness classification ISO8, maintaining a dew point of -40°C continuously. But it is also possible to upgrade this solution to classification ISO7 or a dew point of -60°C. The DryCell can be supplied as both an indoor and outdoor solution. Due to the high degree of pre-engineering of prefabricated building blocks, we can deliver this solution in just a few weeks.

Legolisation means standardisation. Standardisation causes a shift in production. Work is carried out in conditioned spaces such as factory halls. our cleanrooms are manufactured partly or entirely off-site, which means huge savings on transport costs and reduction of inconvenience on-site