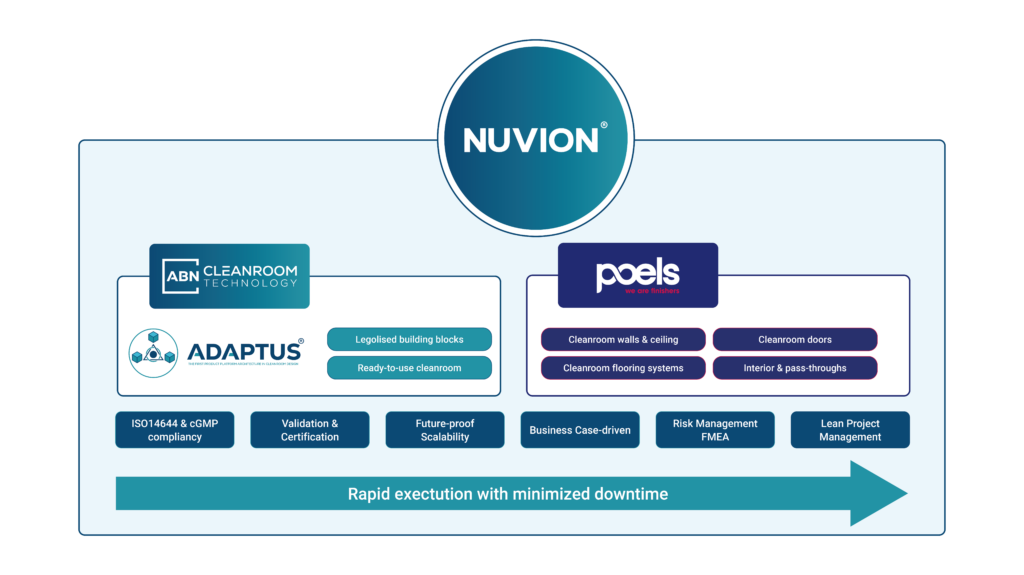

NUVION, a groundbreaking cleanroom and lab space renovation concept from ABN and Poels Labs

NUVION: A new approach for cleanroom renovation

NUVION addresses these challenges by integrating ABN Cleanroom Technology’s expertise in pre-engineered cleanroom solutions with Poels Labs’ efficiency and practical craftsmanship. This collaboration ensures that renovation projects are executed with precision, compliance, and future scalability in mind.

Taking a business case-driven approach, NUVION begins with a thorough analysis to deliver tailored solutions using the ready-to-use ADAPTUS building blocks. This approach not only modernizes cleanrooms to meet current regulatory standards but also prepares them for future growth. By employing risk-based methodologies and lean project management practices, NUVION significantly reduces downtime, minimizes disruption, and ensures that operations remain uninterrupted throughout the renovation process.

NUVION distinguishes itself through its ability to deliver high-quality cleanroom renovations efficiently and effectively, guided by three fundamental pillars:

1. Business Case-driven planning with ADAPTUS expertise

NUVION adopts a systematic approach, starting with detailed risk analyses to build a solid foundation for every project. By utilizing advanced tools such as 3D laser scanning and BIM software, the planning process achieves a high level of precision and ensures seamless integration of modifications. Modular and sustainable ADAPTUS solutions offer exceptional flexibility and scalability, enabling cleanrooms to adapt to future requirements. Combined with lean project plans, this approach ensures timely and efficient execution without compromising quality.

2. Practical Execution and Speed

Poels Labs applies its craftsmanship and in-house expertise to deliver high-quality structural modifications tailored to each project. Key components such as doors, floors, walls, ceilings, and pass-through systems are seamlessly integrated to ensure minimal disruption and optimal efficiency. This action-oriented approach enables rapid transformations while maintaining operational continuity, ensuring that cleanroom functionality is preserved throughout the renovation process.

3. Risk Management and FMEA Methodologies

NUVION combines scientific rigor with practical execution to deliver a comprehensive, end-to-end solution. By incorporating advanced risk management strategies, such as Failure Mode and Effects Analysis (FMEA), NUVION ensures that every aspect of the renovation process aligns with the highest standards of compliance, including ISO 14644 and cGMP. This proactive approach mitigates risks and ensures a smooth, reliable project delivery.

New golden standard for cleanroom renovations

NUVION stands out by seamlessly integrating speed, regulatory compliance, and know-how into its cleanroom renovation projects. Through its productized methodology, NUVION minimizes downtime, meets the strictest industry standards, and incorporates environmentally responsible practices—ensuring that cleanrooms are not only efficient today but also prepared for future expandings.

NUVION sets itself apart by integrating speed, regulatory compliance, and expertise into every cleanroom renovation project. Its productized methodology minimizes downtime, ensures adherence to the highest industry standards, and incorporates sustainable practices—delivering cleanrooms that are efficient today and adaptable for future expansions.

As Gauthier Pauly of Poels Labs remarks, “Whether for small or large cleanroom renovations, NUVION delivers without compromising on quality or speed. That is our strength.”

Ready to elevate your cleanroom standards? Contact us to discover how NUVION can transform your existing cleanroom into a state-of-the-art facility—delivering speed, compliance, and sustainability for the future.

Let's talk cleanrooms

Whether you’re looking for expert advice, a quick answer, or a detailed discussion, we’re here to help. Choose the option that works best for you—call us directly, send us an email, or book a 30-minute meeting at your convenience. Let’s find the best cleanroom solution together!

E-mail us

info@abn-cleanroomtechnology.com

Call us

+32 (0)89 32 10 80

Book a meeting

Book a 30 minute meeting