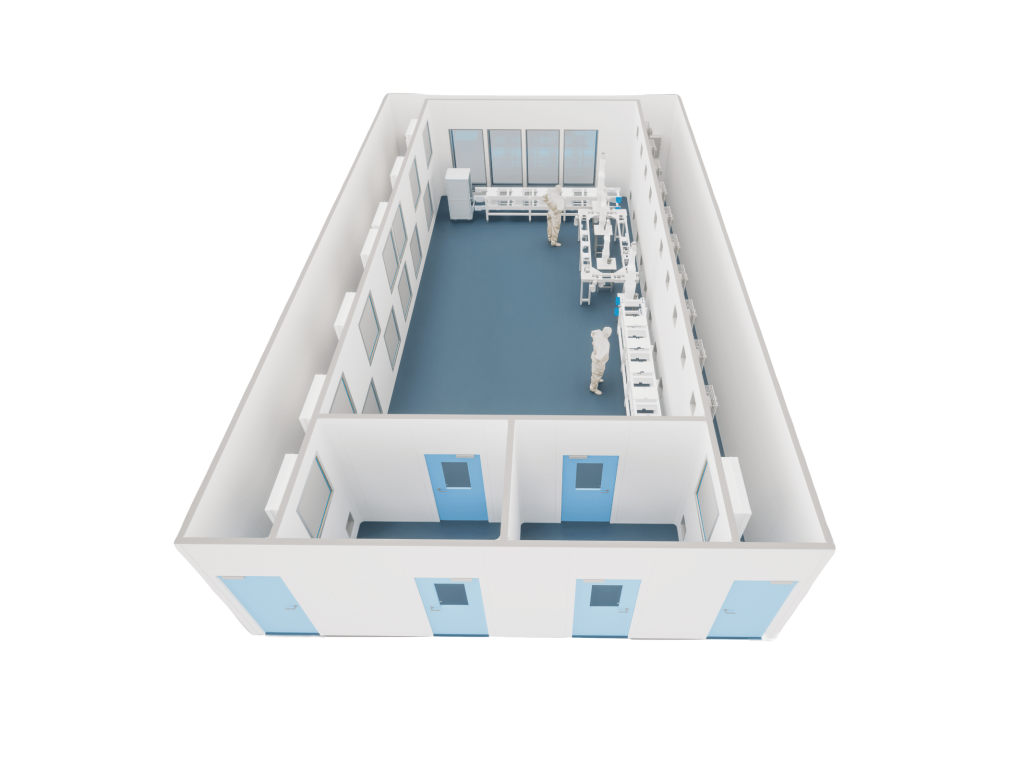

Off-the-shelf cleanrooms

Fast deployment, proven reliability

To meet the unique demands of different industries, we have developed a full range of off-the-shelf cleanroom solutions. Each option is tailored to specific market requirements. For example, we support pharmaceuticals, biotechnology, semiconductors, and high-tech manufacturing.

Moreover, our ready-to-ship cleanrooms guarantee a seamless and reliable fit. As a result, you can accelerate project timelines without sacrificing compliance.

Modular design for efficient scaling

By combining modular design with rapid deployment and proven reliability, our off-the-shelf cleanrooms enable businesses to scale efficiently. At the same time, they maintain the highest standards required for critical operations. Therefore, you benefit from both speed and security.

Our off-the-shelf solutions

At ABN Cleanroom Technology, we know that every industry requires a unique approach to contamination control. In addition, our standardized cleanroom solutions are engineered to meet strict regulatory requirements.

Consequently, each cleanroom is designed with features that ensure optimal performance, quality, and compliance. Explore our product line below:

ICONIC addresses the growing demand for quick and efficient cleanroom solutions. In fact, it is the ideal entry-level option for a wide range of applications.

Classifications

Up to ISO6

Location

Indoor

Price range

Delivery times

6-8 weeks

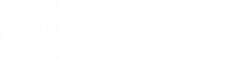

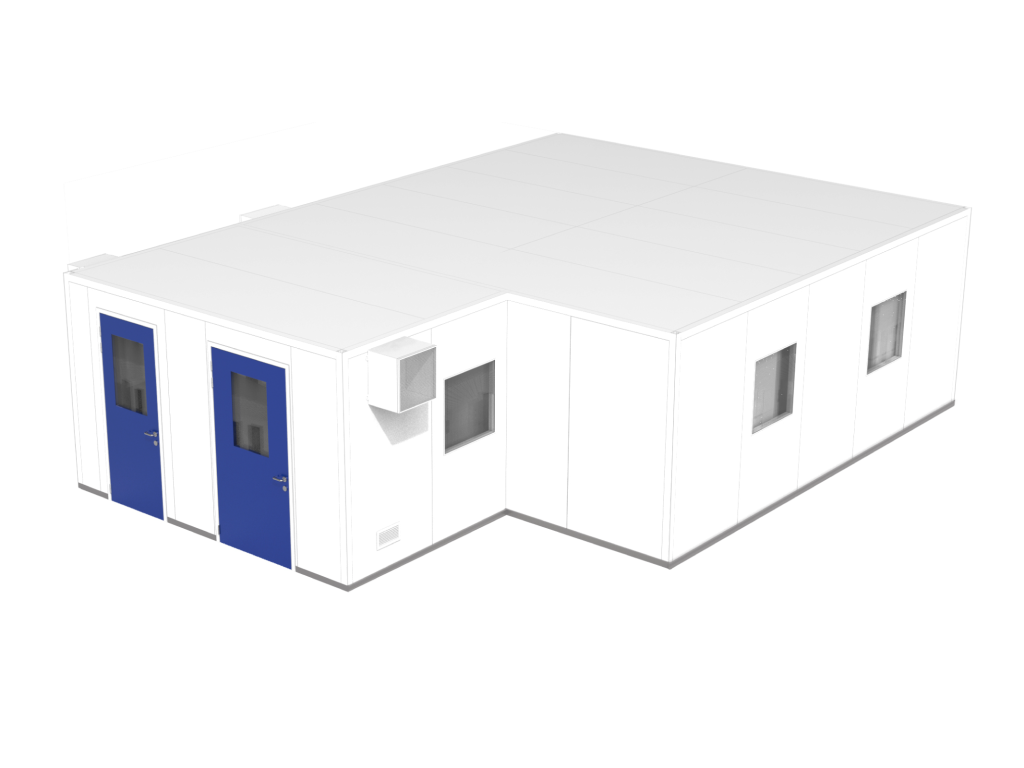

INTEGRA is a modular, off-the-shelf cleanroom solution. It meets ISO and cGMP standards through the integrated VIX concept. Moreover, it provides strong compliance without long lead times.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-15 weeks

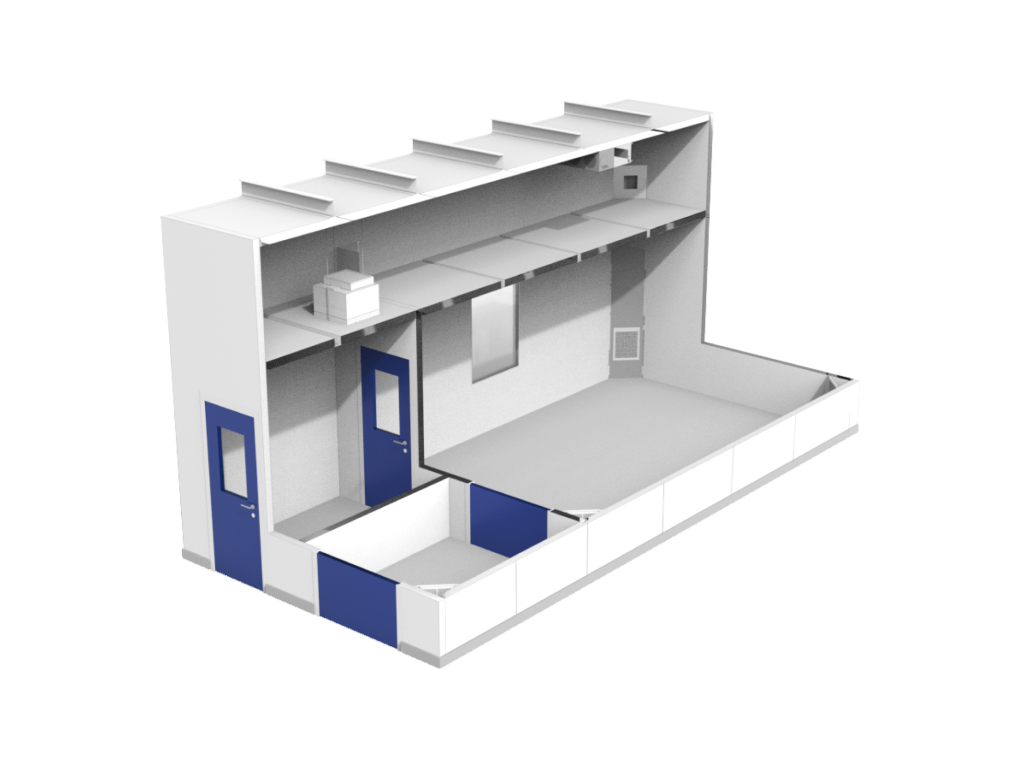

SteriCube ONE is a modular outdoor cleanroom unit. Therefore, it is ideal when indoor space is limited but controlled environments are still required.

Classifications

Up to ISO5

Up to cGMP B

Location

Outdoor

Price range

Delivery times

12-16 weeks

SteriCube VELOX combines multiple SteriCube ONE units to create large, high-performance environments. Consequently, it offers a reliable way to expand operations quickly.

Classifications

Up to ISO5

Up to cGMP B

Location

Outdoor

Price range

Delivery times

14-18 weeks

The MATRIX is a VIX cleanroom with side-mounted plenums. It is designed for facilities with low ceilings. As a result, you maintain optimal airflow and contamination control even in restricted spaces.

Classifications

Up to ISO5

Up to cGMP B

Location

Indoor

Price range

Delivery times

10-14 weeks

Industry-specific cleanroom solutions

In addition to standardized products, the ADAPTUS platform allows us to design industry-specific solutions. For example, we deliver cleanrooms for cell and gene therapy, hospital pharmacies, and other critical environments.

Above all, every project combines modular efficiency with customer-specific flexibility. Therefore, you receive a solution that meets strict industry standards while still adapting to your needs.

DRYCELL

The DRYCELL is a modular dryroom solution designed for ultra-low humidity environments, ensuring precise climate control for sensitive production processes.

HOSPIX

The HOSPIX is a specialized cleanroom solution for hospital pharmacies, designed to ensure PIC/S-compliant medication compounding in a controlled environment.

GENEFAB

GENEFAB is a specialized cleanroom solution for cell and gene therapy production, ensuring GMP compliance and controlled biomanufacturing conditions.

Our industries

What our clients say

Start your cleanroom project

Receive a first estimation within one working day

Tell us about your cleanroom requirements and specifications, and we’ll prepare a first cost estimation for you within one working day. Simply complete the form with as much detail as possible, from classification and size to specific industry or technical needs.

Prefer to speak directly? You can always contact us by phone or email, and our team will be happy to discuss your project.

Let's talk cleanrooms

Whether you’re looking for expert advice, a quick answer, or a detailed discussion, we’re here to help. Choose the option that works best for you—call us directly, send us an email, or book a 30-minute meeting at your convenience. Let’s find the best cleanroom solution together!

E-mail us

info@abn-cleanroomtechnology.com

Call us

+32 (0)89 32 10 80

Book a meeting

Book a 30 minute meeting