Modularization is a design approach that fosters agility and adaptability while providing a foundation for future scalability that is both fast and cost-effective. This approach is increasingly being embraced by manufacturing companies in many different cleanroom industries. As companies strive to accelerate their business plans across a global manufacturing landscape, modular design is becoming a key strategy, with a growing number of cleanroom users recognizing its potential.

In today’s dynamic and ever-changing business environment, flexibility and agility are critical success factors for manufacturing organizations. This is particularly true for companies operating in the life sciences and high-tech sector, where the landscape is constantly evolving and new opportunities and challenges arise with remarkable speed. A modular approach to cleanroom design and construction is becoming an increasingly popular strategy for companies seeking to optimize their operations for the long term.

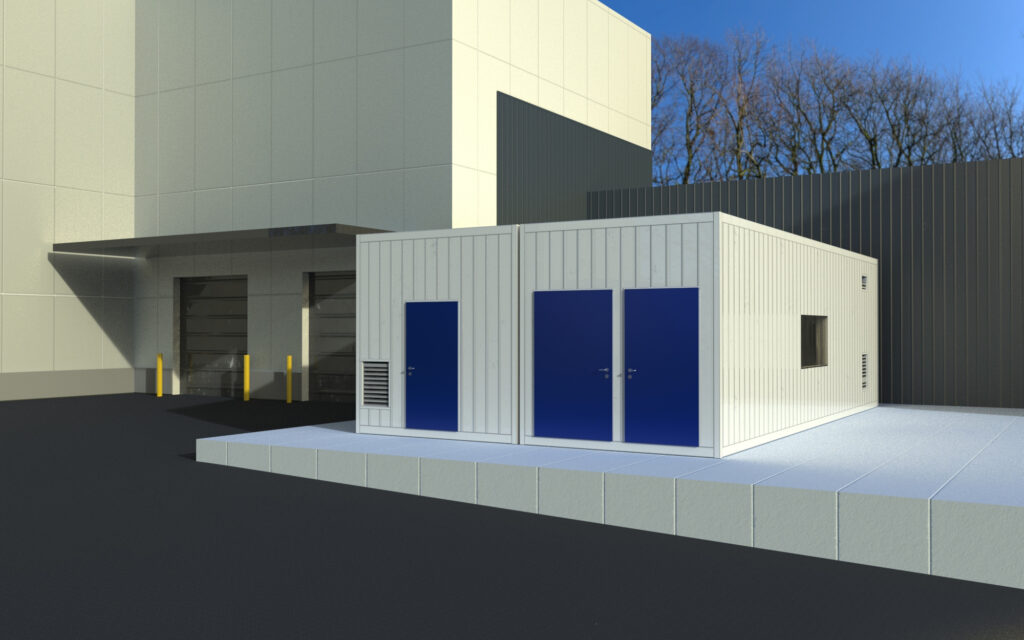

Moving beyond the limitations of bespoke design with our mobile and configurable cleanroom VELOX is advantageous. Not only does VELOX accelerate commercial manufacturing expansion, but it also enables clients to strategically control their facility’s operational costs due to integrated data intelligence. Furthermore, the modular design approach of VELOX enables organizations to more effectively manage their facility’s end-of-life costs by providing the flexibility to relocate modules around the globe as needed.

By embracing modularity as a key design principle, our customer enjoys a range of benefits, including a shorter distance from concept to initial operation, minimized on-site construction works, increased operational efficiency and greater adaptability to changing market conditions. Whether expanding their commercial manufacturing capacity, scaling up production or preparing for future changes, VELOX offers a reliable and cost-effective solution that enables companies to thrive in today’s fast-paced business environment.

Regulatory compliance is just one example of how the standardization granted by modular design can improve operations. Customizing facilities leaves room for inconsistencies between sites. Standardization on the contrary, helps reduce these inconsistencies by establishing a uniform set of guidelines, procedures and specifications that can be applied across different sites. Standardization ensures consistency in cleanroom quality, performance and safety, as well as reduce the risk of construction errors, defects or failures that can result from customizing cleanroom facilities from scratch.

Regulatory compliance is just one example of how the standardization granted by modular design can improve operations. Customizing facilities leaves room for inconsistencies between sites. Standardization on the contrary, helps reduce these inconsistencies by establishing a uniform set of guidelines, procedures and specifications that can be applied across different sites. Standardization ensures consistency in cleanroom quality, performance, and safety, as well as reduce the risk of construction errors, defects or failures that can result from customizing cleanroom facilities from scratch.

Modularity ensures compliance in several ways. Modular design allows for the use of pre-engineered building blocks that have already been certified to meet regulatory standards, reducing the time and effort required to obtain regulatory approval for a new facility. Next to that, modular cleanroom design can be validated more quickly and easily, allowing for faster regulatory approval and a shorter time to market.

In conclusion, modular cleanroom design like VELOX can be a game-changer for the life science and high-tech industry, not just in terms of agility and adaptability but also in regulatory compliance and expansion efforts. By using a modular approach, companies can accelerate their speed-to-market strategy, streamline operations and ensure compliance with regulatory standards across multiple facilities.

Legolisation means standardisation. Standardisation causes a shift in production. Work is carried out in conditioned spaces such as factory halls. our cleanrooms are manufactured partly or entirely off-site, which means huge savings on transport costs and reduction of inconvenience on-site